Description, sociology and dating

The model tambour-front bureau stands on thin feet that are slightly bent outwards. The corpus contains two same sized drawers. On the left and right of these drawers four secret drawers can be found on either side. They are laid with marbled paper as is the outside of the back panel. The cylinder opens by pulling out the writing surface. There are two more drawers hidden under the cylinder. The bureau is topped by a gallery surrounded by a balustrade designed as an open worked rhombic decoration. The corner posts are topped with skittle-shaped ornaments. The bureau is entirely veneered, the surface being structured by a moulding on either side of the corpus optically dividing the top and bottom part and contrasting black ornaments such as the balustrade, the skittle-shaped ornaments as well as two semi-balusters with accompanying mouldings flanking the two big drawers. The furniture type and the overall style of decoration identifies the bureau to have its origin in the Biedermeier. The contrasting classicist ornaments, the cherry wood veneer with its structure being used as an ornament itself and thus being continued on the fronts of the two big drawers and last but not least the feet, known as “Dackelfüße”, are typical for this style. Judging by the appearance of the bureau its origin can be narrowed down to the south of Germany at a period of time around 1820/30. As the Biedermeier was a style of the bourgeoisie the bureau belongs to the pieces of furniture of this class.

Construction and surface

Due to the fact that the bureau is a piece of model furniture its dimensions are quite petit with a height of 42,5 cm, a width of 42 cm and a depth of 24 cm. The corner connections of the corpus and the large drawers are realised as dovetail joints, the front of the corpus as well as the bottom of the large drawers and all connections of the other drawers are butt joined. The back panel sits in a rabbet. The dust panel that serves as front panel and runner at the same time is joined to the side panels with a through dado joint. The feet and the corner posts and the balustrade are fixed to the corpus with mortise and tenon joints. The visible part of the cylinder is made from one piece of solid wood and slides in grooves in the side panel. The part that is hidden in the corpus is realised as tambour, consisting of narrow strips of wood glued to a linen backing. The tambour is connected to the mobile writing surface and that way by pulling it out the cylinder opens. The joints used for the bureau are quite elaborate considering it being a model, although there are joints, mainly the butt joints, that would maybe be replaced by more stable joints in a full-sized piece of furniture.

The contrasting ornaments are lacquered black. The veneered surfaces are varnished, showing the typical satin sheen finish of an aged vanish based on natural resins.

Damage

The overall state of conservation of the bureau was quite good albeit being somewhat uncared-for. The construction was quite stable due to having been reworked which the omnipresent traces of modern glue point towards. The cylinder however did not run smoothly in its slide. The right back corner of the bottom showed woodworm infestation. The mouldings on the sides of the corpus were loose as was the veneer of the sides, the right side of the cylinder slide and the large drawers. Three out of four skittle-shaped ornaments topping the corner posts of the balustrade were missing. On the inside of the bureau one major problem was the mechanical stiffness of the large and the secret drawers. Some of the latter were almost unmovable, additionally most of the textile loops that used to serve as handle were missing.

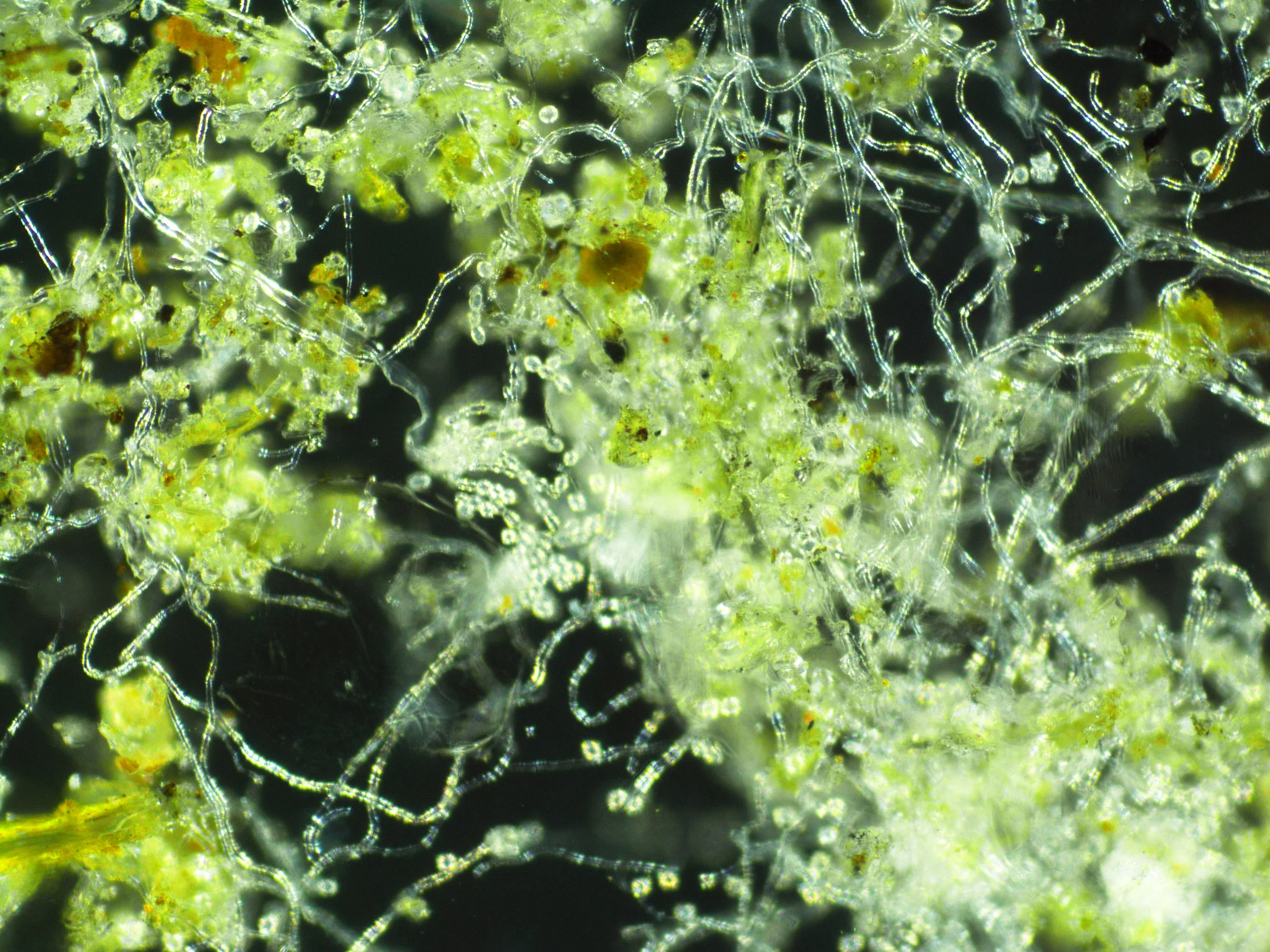

The surface of the entire object was heavily polluted, showing patches of fungal infestation on the outside as well as the inside. Whilst the varnish still seemed to be quite intact there was a matte layer of presumed furniture polish covering large areas of it. Gloss level and colour of the moulding on the right side as well as some parts of the balustrade did not fit the rest thus could be assumed to be reworks.

The marbled paper on drawers and back panel was loose, torn and partially showed patches of decolouration.

The majority of the damages are likely to have been caused by poor climatic conditions.

Microscopic photograph of the fungi

Scientific examination

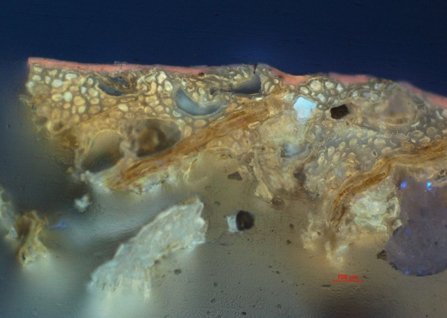

To begin with the types of wood used for the bureau were determined. As there was only replacement work to be done on the bottom of the bureau and on the cylinder slide only this part was determined microscopically (The wood was determined microscopically based on Grosser, D. (1977). Die Hölzer Mitteleuropas. Berlin, Heidelberg, New York: Springer.). It turned out to be pinewood (Pinus sylvestris L.) for the bottom and pearwood (Pyrus comunis) for the slide. The type of wood of the veneer is cherry (Prunus avium). The surface was determined employing various techniques. First of all it was examined using ultraviolet light (The ultraviolet lamp used: UVAHAND 250 GS Fa. Hönle, uv-technology, Gräfeling/München), which showed that the majority of the varnished surface has an orange fluorescence that is typical of natural resins, especially shellac. The areas that had already been conspicuous during the optic examination by differing in gloss level and colour showed a blueish-milky fluorescence that indicates a modern nitrocellulose lacquer. Inside the corpus as well as on the outside of the bottom there are large patches of a substance with whiteish fluorescence which leads to the assumption of a rework using generous amounts of modern glue.

The different areas of the surface were then tested regarding their solubility in order to find a solvent to clean the varnished surface. The best results were achieved with aqua dist., the varnish with the orange fluorescence is ethanol soluble which supports the assumption of it being based on natural resins. In the areas that showed blue fluorescence the lacquer is stable to the common solvents such as aqua dist., ethanol, white spirit (100-140°C), isopropanol, Shellsol T. To further determine the latter finish a test for cellulose nitrate was performed that had a positive result (A scrape sample of the lacquer was dissolved in a few drops of amyl acetate in a micro test-tube. Some diphenylamine crystals were added. Slowly a drop of concentrated acetic acid was poured into the mixture, instantly initiating a blue staining.). Lastly cross-section samples of an area with orange fluorescence as well as one with blue fluorescence were analysed microscopically. Both showed only one layer of clear varnish with an orange respectively blue fluorescence. This indicates that the areas that have an orange fluorescence are likely to still be the original varnish whilst the areas that have a blue fluorescence were completely replaced. This applies to the moulding on the right side of the corpus and to parts of the black balustrade.

UV-photograph, front

Analysis of a cross-section sample of the varnish fluorescing orange under UV light

UV-photograph, right side

Analysis of a cross-section sample of a black replacement under UV light

Restoration

The first and most important step was to remove the fungal infestation, which was taken off with a vacuum cleaner equipped with a HEPA filter (Muntz-Museums-Staubsauger 555 MU E HEPA). The areas of raw wood were then cleaned with a mixture of water and isopropanol (3:7). To have better access to the inside of the bureau the back panel was removed by sewing through the modern glue that held it in place. Afterwards the constructional work that mainly concerned restoring the smooth running of the cylinder in its slide was done. As there was no possibility to dismantle the cylinder the needed replacement had to be done on the slide. The slide was then cleaned and then reinforced with a fitted replacement made from pearwood onto which some wax was applied. The stoppers on the bottom of the writing surface were replaced as well. As a result the cylinder was sitting firm in the slide and running smoothly again. The area of woodworm manifestation was first evened out with little rods and then replaced with a fitted replacement in pinewood. It was stained with the water-based stain Körnerbeize (Nussbaumbeize by Kremer Pigmente) to match the surrounding wood. To diminish the mechanic stiffness of the large drawers the bottoms of these were firmly glued afresh. The removal of the back panel of the bureau allowed to take out the little racks containing the secret drawers. That way the drawers could be removed, the rack was cleaned from excess modern glue using acetone gel and glued together anew minding the drawers to fit in. Loose parts such as the moulding on the right and left were glued down as was the loose veneer. The glue was massaged into cracks of the slightly warmed veneer which was then pressed down for two hours with hand clamps and plexiglass interleaving Hostaphan foil. This was opened to remove the excess glue and then pressed down again over night. The missing skittle-shaped ornaments were replaced with ones that were turned taking the remaining one as model. They were stained with a mixture of Körnerbeize (Nussbaumbeize by Kremer Pigmente) and Irgasperse (a water-soluble metal complex dye by BASF) and finished with orange shellac (by Kremer Pigmente). Hide glue (skin and bone 1:1) was used for bonding.

With all the constructional work done the work concerning the surface was next. The entire surface was cleaned with aqua dist., in some areas saliva was used additionally, thoroughly afterwards cleaning with aqua dist. The matte layer was taken off with white spirit (100-140°C). To achieve an even gloss level micro-crystalline wax polish (Renaissance Wax) was applied in some areas. The result was the nice, semi-gloss finish of an aged shellac varnish. Several layers of orange shellac (by Kremer Pigmente) were applied to the replacements with unsuitable colour and gloss level and burnished afterwards using abrasive linen (Micromesh, grain 4000-12000, by CS Cybernetic-Systems GmbH).

Back panel, pre-restoration

Back panel, post-restoration

The marble paper was restored by first consolidating it with wheat starch paste. This type of glue was chosen due to its long processing time and its elasticity. The paste was prepared as a 40 % solution and heated in a bain-marie frequently stirring until transparent. After cooling down completely the paste was applied under the paper using a spatula, diluting it with a small amount of water. It is important to use just as much water as needed to make the paste processible while avoiding stains due to water spotting. The paper was pressed down using blotting paper to immediately absorb any excess water. In areas of decolouration, mainly on the edges of the paper, shellac (bleached and dewaxed, by Kremer Pigmente) was applied. These areas were then neutrally retouched with watercolours (by Schmincke). The textile loops were replaced with a cotton ribbon stained with Irgasperse (by BASF) to fit the remains of the original loops.

Model cylinder-front bureau, pre-restoration

Model cylinder-front bureau, post-restoration